|

|

Industrial Logistics Labeling Software

-

Version

9.2.3.1

Industrial Logistics Labeling Software

-

Version

9.2.3.1

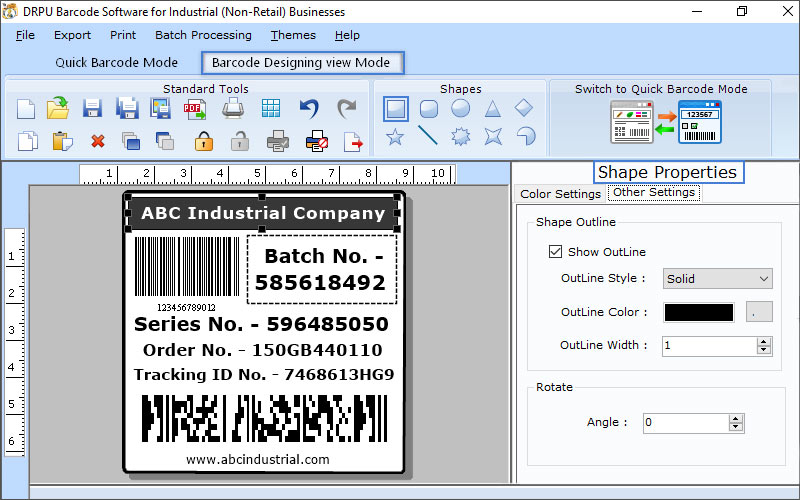

To handle their warehouse operations, several companies utilise various barcode typefaces. Good barcode systems reduced human errors and never invert numbers, skip a line or misread a number while scanning of a bar-coded product in a warehouse. Manually entering data or checking the product by hand is sometimes driven your business slow and decrease your supply and packaging. You can keep your warehouse safe from such mistakes by using barcodes. Warehouse scanners, portable scanners, and mobile device scanners all provide immense performance and accuracy at a high rate. Orders are filled with high accuracy and in less time because of bar-coding technology. In the warehouse, barcodes assist in filling orders that are out of stock while maintaining company performance. A barcode is printed on a product before it is sent to the assembly line on a production line. To maintain the proper flow and precision, all of the components of a product are bar-coded before assembly. Barcodes are being used in more and more warehouse sectors. Picking, receiving, packing, shipping/manifesting, put away returns, labour tracking, cycle counts, replenishment, and value-add elements are just a few examples. To handle all of these divisions, Barcode Generator Software for Warehouse Industry designs and prints all forms of barcodes. A barcode on a shipping package can be used to identify the order and gain access to information such as the contents of the shipment, the customer's identity, the delivery address, and the shipping method. You can track labour time at a warehouse in a far more future-oriented approach than you can with manual paper-based time tracking. Barcodes helps making business process smooth and much more efficient. Barcodes enable the tracking and storage of information about products, from single items to massive inventories of thousands of pieces.

|